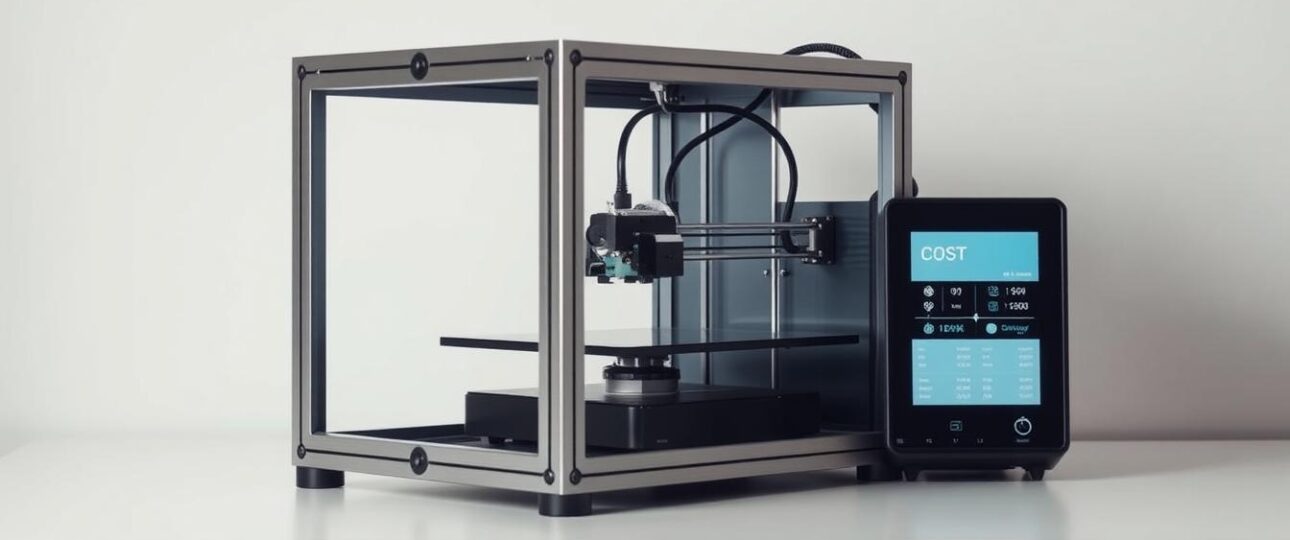

The cost of a 3D printer is a crucial consideration for individuals and businesses looking to adopt this technology. As 3D printing continues to revolutionize manufacturing and production, understanding the associated costs is essential for making informed decisions.

The cost of a 3D printer can vary widely, depending on factors such as the type of technology used, the size of the printer, and the materials it can handle. A comprehensive guide to 3D printing costs can help navigate these variables and provide a clearer understanding of what to expect.

Table of Contents

Key Takeaways

- Understanding the different types of 3D printing technologies and their associated costs.

- Factors that influence the cost of a 3D printer.

- The importance of considering the total cost of ownership, including materials and maintenance.

- How to choose the right 3D printer for your specific needs and budget.

- Tips for getting the most out of your 3D printing investment.

The Evolution and Impact of 3D Printing

Additive manufacturing, commonly known as 3D printing, has transformed the way we create objects. This technology has evolved significantly over the years, from its initial use in industrial prototyping to its current applications in various fields, including personal use.

What is Additive Manufacturing?

Additive manufacturing is a process of creating objects by layering materials such as plastics, metals, and ceramics. Unlike traditional subtractive manufacturing, which involves cutting or drilling, additive manufacturing builds objects from the ground up. This method allows for the creation of complex geometries and structures that would be difficult or impossible to produce with traditional manufacturing techniques.

From Industrial Prototyping to Home Use

Initially, 3D printing was used for rapid prototyping in industrial settings, allowing companies to test and refine product designs quickly. Over time, advancements in technology have made 3D printing more accessible and affordable, leading to its adoption in homes and small businesses.

Key Milestones in 3D Printing Development

The development of 3D printing technology has been marked by several key milestones:

- 1980s: The first 3D printing technologies were developed, including Stereolithography (SLA).

- 1990s: Fused Deposition Modeling (FDM) became popular, making 3D printing more accessible.

- 2000s: The expiration of key patents led to the rise of open-source 3D printing projects, such as RepRap.

- 2010s: 3D printing began to be used in various industries, including healthcare, aerospace, and automotive.

| Year | Milestone | Impact |

| 1984 | SLA technology developed | First commercial 3D printing technology |

| 1992 | FDM technology introduced | Made 3D printing more affordable and accessible |

| 2009 | Open-source 3D printing projects emerged | Led to a community-driven development of 3D printing technology |

The evolution of 3D printing has been rapid, with significant advancements in technology and reductions in cost. As a result, 3D printing is now used in a wide range of applications, from hobbyist projects to industrial manufacturing.

Entry-Level 3D Printers: Budget Options

The market for entry-level 3D printers has expanded significantly, providing budget-friendly options for hobbyists and beginners. This growth has made it easier for new users to enter the world of 3D printing without breaking the bank.

DIY Kits ($100-$300)

DIY kits are an attractive option for those who enjoy assembling their own devices. These kits usually cost between $100 and $300 and provide a hands-on learning experience. Popular DIY kits include brands like Creality and Prusa.

Ready-to-Use Budget Models ($200-$500)

For those who prefer a plug-and-play experience, ready-to-use budget models are available in the $200-$500 range. These printers are pre-assembled and ready to print out of the box. Monoprice and FlashForge are well-known brands in this category.

What Features to Expect at This Price Range

Entry-level 3D printers typically offer a build volume of around 200x200x200 mm, heated beds, and support for common filament types like PLA and ABS. Print resolution can vary, but most can achieve layer heights of 0.1 mm or lower.

Common Limitations of Budget Printers

While budget-friendly, these printers often have limitations such as less robust construction, fewer calibration options, and potentially lower print quality compared to higher-end models. As one expert notes,

“Budget printers are great for learning, but they may require more maintenance and troubleshooting.”

In summary, entry-level 3D printers offer a great starting point for newcomers. By understanding the features and limitations, buyers can make informed decisions that suit their needs and budget.

Mid-Range 3D Printers for Enthusiasts

For enthusiasts looking to elevate their 3D printing experience, mid-range printers offer a perfect blend of quality and affordability. These printers are designed to meet the demands of hobbyists and serious makers who require more than what entry-level devices can offer.

Hobbyist Models ($500-$1,000)

Hobbyist models in the mid-range category are ideal for those who are serious about 3D printing but are on a budget. These printers typically offer improved print resolution, larger build volumes, and more reliable performance compared to entry-level models. Brands like Prusa and Creality are well-known for their high-quality hobbyist-grade printers.

Prosumer Options ($1,000-$2,000)

Prosumer options take 3D printing to the next level with advanced features such as heated chambers, dual extrusion, and high-speed printing capabilities. These printers are perfect for enthusiasts who are looking to produce complex prints with high precision. Printers from brands like Ultimaker and MakerGear are popular among this group.

Key Features and Capabilities

Mid-range 3D printers often come with a host of features that enhance the printing experience. These include:

- Improved print resolution and quality

- Larger build volumes for bigger prints

- Advanced temperature control systems

- Dual extrusion for multi-material prints

Popular Mid-Range Printer Brands

Some of the most respected brands in the mid-range 3D printing market include:

“Prusa Research has been at the forefront of 3D printing innovation, offering some of the best mid-range printers available.” – 3D Printing Expert

As the 3D printing landscape continues to evolve, mid-range printers are becoming increasingly sophisticated, offering enthusiasts a wide range of options to suit their needs and budgets.

Professional 3D Printers

For businesses and organizations requiring precise and reliable 3D printing, professional-grade printers are the solution. These advanced machines are designed to deliver high-quality prints with intricate details, making them indispensable in various industries.

Professional Desktop Models ($2,000-$5,000)

Professional desktop 3D printers offer a balance between cost and performance. They are ideal for businesses that need high-quality prints without the hefty price tag of industrial-grade machines. These printers are capable of producing complex geometries and are often used in office settings.

Industrial-Grade Printers ($5,000+)

Industrial-grade 3D printers are the pinnacle of 3D printing technology, offering unparalleled print quality, large build volumes, and advanced features. They are used in demanding applications across various sectors.

Industries Benefiting from Professional 3D Printing

- Aerospace: for producing lightweight, complex components.

- Healthcare: for creating custom implants, prosthetics, and surgical models.

- Automotive: for prototyping and manufacturing parts.

- Education: for enhancing research and teaching capabilities.

As noted by industry experts, “The adoption of professional 3D printing technology is transforming industries by enabling the rapid production of complex parts with high precision.” This shift is not only improving product quality but also reducing production times and costs.

The applications of professional 3D printing are vast and continue to grow as the technology advances. With their ability to produce high-quality prints, professional 3D printers are becoming essential tools in modern manufacturing and design.

Factors Affecting 3D Printer Costs

Understanding the factors that affect 3D printer costs is crucial for making an informed purchase decision. The cost of a 3D printer can vary widely based on several key elements.

Printing Technology Types (FDM, SLA, SLS)

The type of 3D printing technology used significantly impacts the cost. Fused Deposition Modeling (FDM) is generally more affordable, with prices starting from a few hundred dollars. Stereolithography (SLA) and Selective Laser Sintering (SLS) technologies are more expensive due to their complex printing processes and higher precision, often costing several thousand dollars.

Build Volume and Size Considerations

The build volume, or the size of the objects a 3D printer can produce, is another critical factor. Larger build volumes require more materials and more complex machinery, increasing the cost. Printers with larger build volumes are typically more expensive.

Print Quality and Resolution Specifications

Print quality and resolution are directly related to the printer’s ability to produce detailed and accurate objects. Higher resolution printers, which can produce finer details, are generally more costly due to the advanced technology required.

Speed and Efficiency Metrics

The speed at which a 3D printer can produce objects also affects its cost. Faster printers that can maintain high-quality outputs are more expensive because they incorporate advanced technologies that enable quicker production without sacrificing quality.

By considering these factors, buyers can better understand the costs associated with different 3D printers and make a more informed decision based on their specific needs and budget.

The Hidden Costs of 3D Printing Technology

Beyond the initial investment in a 3D printer, there are several hidden costs that users should be aware of. These costs can significantly impact the overall expense of owning and operating a 3D printer.

3D Printing Materials Expenses

The cost of 3D printing materials can vary widely depending on the type and quality. Common materials like PLA and ABS can range from $20 to $50 per kilogram.

Maintenance and Replacement Parts

Regular maintenance is crucial for the longevity of a 3D printer. Costs for replacement parts, such as nozzles and belts, should be factored into the overall budget.

Software and Design Tools

While some 3D modeling software is available for free, professional-grade tools can be expensive. Costs for these tools should be considered, especially for commercial use.

Energy Consumption Costs

3D printing can be energy-intensive. The cost of electricity to operate a 3D printer over time can add up, especially for high-usage environments.

| Cost Category | Estimated Cost |

| 3D Printing Materials | $20-$50 per kg |

| Replacement Parts | $10-$50 per part |

| Software | $0-$1,000+ |

| Energy Consumption | $5-$50 per month |

3D Printing Materials: Cost Breakdown

Understanding the costs of 3D printing materials is crucial for both hobbyists and professionals. The expenses associated with these materials can significantly impact the overall cost of 3D printing projects.

Common Filaments (PLA, ABS, PETG)

The most commonly used filaments in Fused Deposition Modeling (FDM) 3D printing are PLA, ABS, and PETG. PLA is a popular choice due to its ease of use and biodegradable properties, costing between $15 to $30 per kilogram. ABS is known for its durability and impact resistance, priced around $20 to $40 per kilogram. PETG combines the benefits of PLA and ABS, offering strength and flexibility, typically costing $25 to $35 per kilogram.

Resins for SLA Printing

Resins used in Stereolithography (SLA) printing are generally more expensive than FDM filaments. The cost of SLA resins can range from $50 to $150 per liter, depending on the brand and quality.

Specialty and Composite Materials

Specialty materials, such as conductive, magnetic, or wood-filled filaments, offer unique properties for specific applications. These materials are typically more expensive, with prices ranging from $30 to $100 per kilogram.

Material Storage Requirements

Proper storage of 3D printing materials is essential to maintain their quality and longevity. Filaments should be kept dry, and resins should be stored in a cool, dark place.

Home 3D Printing vs. 3D Printing Services

When considering 3D printing for personal or professional projects, one of the first decisions is whether to invest in a home 3D printer or use a professional 3D printing service. This decision hinges on several factors including the cost of the printer, the cost of printing materials, and the complexity of the projects.

Cost Analysis of Owning a Printer

Owning a 3D printer involves initial hardware costs, ongoing material expenses, and potential maintenance costs. The initial investment for a decent 3D printer can range from a few hundred to several thousand dollars.

When to Use Professional 3D Printing Services

Professional 3D printing services are ideal for projects that require high precision, large build volumes, or specialized materials. They offer expertise and equipment that may not be feasible for personal or small business investments.

Price Comparison for Common Projects

| Project Type | Home 3D Printing Cost | Professional Service Cost |

| Simple Prototype | $5-$20 | $50-$100 |

| Complex Model | $20-$100 | $100-$500 |

| Large Scale Model | $100-$500 | $500-$2,000 |

The table above illustrates the cost differences between home 3D printing and professional 3D printing services for various project types. For simple prototypes, home 3D printing is significantly more cost-effective. However, for complex or large-scale models, while the initial cost of home 3D printing might be lower, professional services can offer better quality and durability.

Return on Investment for 3D Printing

Understanding the return on investment (ROI) for 3D printing is crucial for individuals and businesses looking to leverage this technology. The ROI for 3D printing can vary significantly depending on the user group, application, and specific technology used.

ROI for Hobbyists and Makers

For hobbyists and makers, the ROI is often measured in terms of the value of the projects they can complete. 3D printing allows for the creation of complex designs that would be difficult or impossible to produce with traditional manufacturing methods. While the initial investment in a 3D printer can be significant, the cost per project can be relatively low, especially when using affordable materials like PLA.

ROI for Small Businesses

Small businesses can benefit from 3D printing by reducing prototyping costs and accelerating product development cycles. The ability to quickly iterate on designs can significantly reduce the time-to-market for new products. Additionally, 3D printing can be used for producing custom parts and tools, further enhancing operational efficiency.

ROI for Educational Institutions

Educational institutions are increasingly adopting 3D printing to enhance STEM education. By integrating 3D printing into their curricula, schools can provide students with hands-on experience in design and manufacturing, preparing them for careers in technology and engineering. The ROI in this context is not just financial but also includes the value of enhanced educational outcomes.

Case Studies of Successful Implementations

Several organizations have successfully implemented 3D printing to achieve significant ROI. For example, a small design firm reduced its prototyping costs by 50% after adopting 3D printing technology. Educational institutions have reported improved student engagement and understanding of complex concepts through the use of 3D printed models.

In conclusion, the ROI for 3D printing is multifaceted and depends on the specific application and user group. By understanding the potential benefits and costs, individuals and organizations can make informed decisions about investing in 3D printing technology.

Industrial 3D Printing: Advanced Solutions

Advanced 3D printing solutions are redefining industrial manufacturing. These cutting-edge technologies are not only enhancing production efficiency but also enabling the creation of complex geometries and structures that were previously impossible to produce.

Metal 3D Printing Systems and Costs

Metal 3D printing is a significant advancement in industrial manufacturing, allowing for the production of durable, high-strength parts. Systems like Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) are leading the way. The cost of metal 3D printing systems can range from $200,000 to over $1 million, depending on the technology and capabilities.

Large-Format 3D Printing Options

Large-format 3D printing is revolutionizing industries such as construction and aerospace by enabling the production of large-scale parts. Technologies like Big Area Additive Manufacturing (BAAM) are making it possible to print structures that were previously too large or too complex.

Multi-Material Systems

Multi-material 3D printing systems allow for the simultaneous use of different materials, enhancing the versatility of 3D printing. This capability is particularly valuable in industries requiring parts with varied material properties.

Specialized Industry Applications

As quoted by a leading industry expert, “3D printing is not just about making things faster; it’s about making things better, with properties that can’t be achieved through traditional manufacturing.”

“The future of manufacturing is not just about additive or subtractive methods alone, but about how these technologies can be integrated to create hybrid systems that leverage the strengths of both.”

Industrial 3D printing is transforming sectors such as aerospace, automotive, and healthcare by providing advanced solutions for complex manufacturing challenges.

File Formats and Software Costs in 3D Printing

Beyond the initial investment in a 3D printer, the costs of software and compatible file formats can significantly impact the overall expense. Understanding these elements is crucial for anyone looking to dive into the world of 3D printing.

Working with STL Files

The STL (STereoLithography) file format is one of the most commonly used formats in 3D printing. It represents the surface geometry of a 3D object using triangular facets. While STL files are widely supported, they have limitations, such as not being able to store color or texture information.

The Advantages of 3MF Files

The 3MF (3D Manufacturing Format) file format is gaining popularity as a more advanced alternative to STL. It supports not only the geometry of the object but also other critical data like color, materials, and lattice structures. This makes 3MF files more versatile and potentially more cost-effective in the long run.

Free vs. Paid 3D Modeling Software

3D modeling software is essential for creating the files that 3D printers use. There are both free and paid options available, each with its own set of features and limitations. Free software like Blender or Tinkercad can be a good starting point, while paid software like Autodesk Fusion 360 or SolidWorks offers more advanced capabilities.

Slicing Software Options

Slicing software is necessary to convert 3D models into layers that a 3D printer can understand. Popular slicing software includes Cura, Simplify3D, and Slic3r. The choice of slicing software can affect print quality and efficiency.

| Software | Type | Cost | Key Features |

| Blender | 3D Modeling | Free | Advanced modeling, animation, and rendering |

| Cura | Slicing | Free | User-friendly interface, customizable print settings |

| Autodesk Fusion 360 | 3D Modeling | Paid | Parametric and direct modeling, simulation tools |

| Simplify3D | Slicing | Paid | Advanced print settings, multi-material support |

When choosing 3D modeling and slicing software, it’s essential to consider the specific needs of your projects, including the level of detail required, the type of 3D printer you’re using, and your budget.

Conclusion: Making the Right Investment in 3D Printing

Investing in 3D printing technology requires a comprehensive understanding of the costs involved, from the initial purchase price to ongoing expenses for materials and maintenance.

This comprehensive guide has walked you through the various factors that affect 3D printer costs, including printing technology types, build volume, print quality, and speed.

When considering an investment in 3D printing, it’s essential to evaluate your specific needs and applications, whether for hobbyist projects, professional use, or industrial manufacturing.

By understanding the different types of 3D printing technologies, such as FDM, SLA, and SLS, and their associated costs, you can make an informed decision about the best 3D printing solution for your needs.

Ultimately, making the right investment in 3D printing involves balancing your budget with your performance requirements, ensuring that you get the most out of your 3D printing technology.

FAQ

What is the average cost of a 3D printer?

The average cost of a 3D printer varies widely, from under $200 for entry-level models to over $5,000 for professional and industrial-grade printers.

What factors affect the cost of a 3D printer?

The cost of a 3D printer is influenced by factors such as the type of printing technology (FDM, SLA, SLS), build volume, print quality, and speed.

What are the hidden costs associated with 3D printing?

Hidden costs include expenses for 3D printing materials, maintenance, replacement parts, software, and energy consumption.

How much do 3D printing materials cost?

The cost of 3D printing materials varies depending on the type, with common filaments like PLA and ABS costing between $20-$50 per kilogram, and specialty materials costing significantly more.

Is it cheaper to own a 3D printer or use a 3D printing service?

The cost-effectiveness of owning a 3D printer versus using a 3D printing service depends on the frequency and volume of printing, with owning a printer being more cost-effective for frequent users.

What file formats are commonly used in 3D printing?

STL and 3MF are common file formats used in 3D printing, with STL being widely supported and 3MF offering additional features and advantages.

What are the costs associated with 3D modeling software?

The cost of 3D modeling software varies, with free options like Tinkercad and Fusion 360 available, as well as paid software with more advanced features.

How does the build volume of a 3D printer affect its cost?

The build volume of a 3D printer can significantly impact its cost, with larger build volumes typically resulting in higher costs.

What is the return on investment (ROI) for 3D printing?

The ROI for 3D printing varies depending on the user group, with hobbyists, small businesses, and educational institutions experiencing different benefits and cost savings.

What are the benefits of using industrial 3D printing solutions?

Industrial 3D printing solutions offer advanced capabilities, including metal 3D printing, large-format printing, and multi-material systems, enabling complex and high-precision applications.